Features & Benefits

Standard Equipment

• Touch Pad Interactive Display Screen

• ASME/CRN code pressure vessels

• Logic Pro Advanced Control System

• Field adjustable operating parameters

• System Run/Standby Selector switch

• Emergency stop button and alarm

• Premium Inlet Switching Valves with 3 year warranty

• Separate High and Low Voltage Control Boxes with Single Point

Power Connections

• Tri-temp Heater Control System

• Heater Protection Over-Temperature Shut Down with Alarm

• Low Watt Density Heaters

• Exhaust Temperature Monitors

• Tuned Regeneration Temperature Control with dual contactors

• Industrial Duty Blower (iDBPE Only)

• Control Air Regulating Valve with Gauge and Orifice Union

• Control Air Filter (Required Only on iDHPE/iDBPE-1000 and Larger)

• -400F Pressure Dew Point Standard

• Adjustable/Selectable 2% Stripping Cycle (iDBP Only)

• Heatless Back-Up Mode

• Re-Pressurization Circuit

• Low Temperature Alarm

• Premium Directional Purge, Outlet and Blower Check Valves rated

for high temperature service

• Premium High Temperature Exhaust Valves

• Premium USA activated Alumina Desiccant

• Full Flow Safety Relief Valves

• Heater Circuit Insulation and Aluminum Jacketing

Mojave® Heat Reactivated Dessicant Air Dryers

Heat Reactivated Regeneration

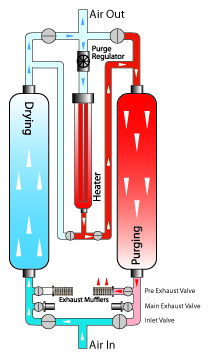

ICP heat reactivated desiccant dryers use the adsorption method to remove moisture from compressed air. Pressure dew points of -40°F/C to as low as -70°F (-56°C) are achieved by directing the flow of saturated compressed air over a bed of desiccant. As the saturated compressed. In order to fully and effectively regenerate the off line saturated tower of the iDHPE series , ICP utilizes the most advanced and highly tuned procedure in the industry. A regulated amount of already dried process air (approx. 7%) is heated by way of a low watt density heater and passed down (counter current) through the desiccant bed. This heated purge air, exhausted to atmosphere, removes all of the collected moisture adhered to the desiccant from the previous drying.

Mojave Blower Purge Dessicant Air Dryers

Blower Purge Regeneration

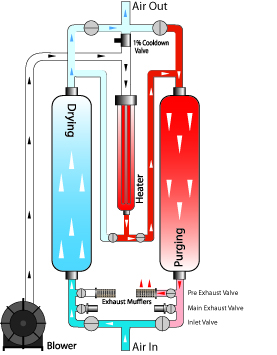

The iDBPE series of dryers also use heated air to regenerate the off line tower. However none of the process air is used during regeneration. A high efficiency packaged blower assembly directs only heated atmospheric air counter current through the desiccant bed, removing all of the moisture that was collected during the previous drying cycle. Dew point spikes or heat bump can be avoided by tuning the regeneration cycle to meet the application.